Section: Engineering Project Management

Engineering Project Management

An Extension of Your Team

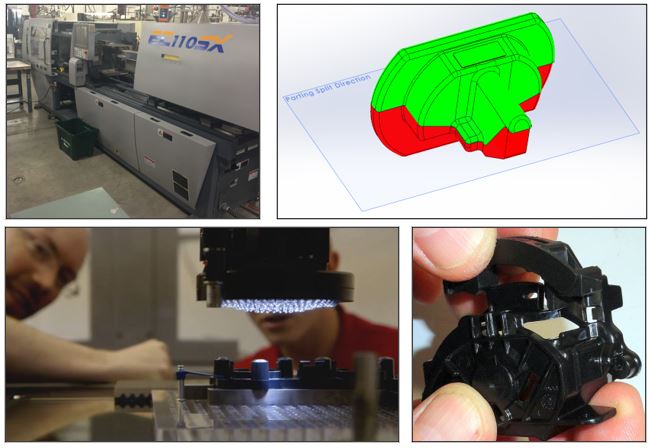

MMI has six Engineers on staff to propel DFM, manage projects from napkin sketch to production. This includes custom automation to make your parts faster, better and more repeatable. Think of our engineers as an extension of your team for design consultation, material selection, specifications and technical training through our seminars and DFM workshops.

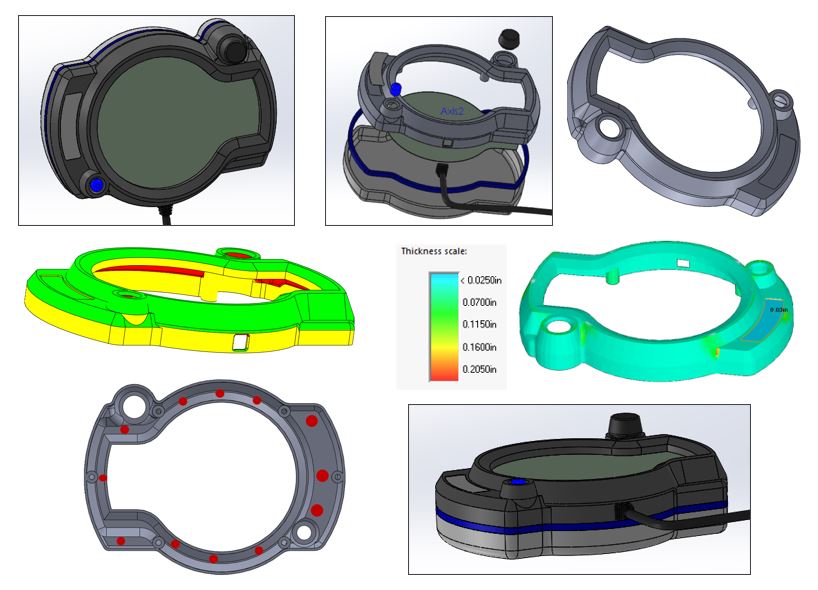

DFM ExampleDesign for Manufacturability (DFM)

- Highly skilled in CAD, simulation, and review of your FEA data

- Engineering driven conversations and solutions based on your application

- Strong GD&T Experience, Correlation to Measurement Techniques

- Experts in injection mold tooling, processes and automation

- Direct Collaboration on Part Iterations and Effects on Tooling

Section: Seminars and Workshops

Seminars and Workshops

Move Up a Level

Modern Molding has been providing free Plastic Design for Manufacturability (DFM) seminars, workshops and lunch-and-learns for more than 15 years for our valued customers. These events take place at our customers or on-site and MMI and throughout our facility. Our seminars are not a sales pitch and they are not the dry presentation and a donut you may be used to. They are interactive and hands-on small group experiences where the participants are a major part of the success of the event. Contact us to learn more these opportunities and see our News sections for upcoming events.