Section: Manufacturing Quality

Manufacturing Quality

Molding and Monitoring Success

MMI’s state of the art production facility includes new injection molding machines, automation and material handling equipment to make your product as efficiently as possible.

Robust, Scientific Molding

- 30 ton up to 390 ton with 0.6 oz. up to 30 oz. shot capacity

- Real-Time Production Monitoring via IQMS

- Bar Coded Labels (Warehouse Management System) via IQMS

- Automation Focused utilizing press top robots for things such as insert loading, part picking, and sorting

- Actively moving towards all electric presses

- Electronic data storage mold and cycle set- up

- Standardization is key as a long time user of Toshiba(now Shibaura) presses

Production molding using decoupled Molding principles. This creates higher quality and more consistent parts. More consistency at the press allows for better material planning, and ultimately on time delivery to our customers.

Material drying and conveying using state of the art Motan drying bins. Material moisture analysis done to confirm that material is dry per the manufacturers specifications. No guessing needed.

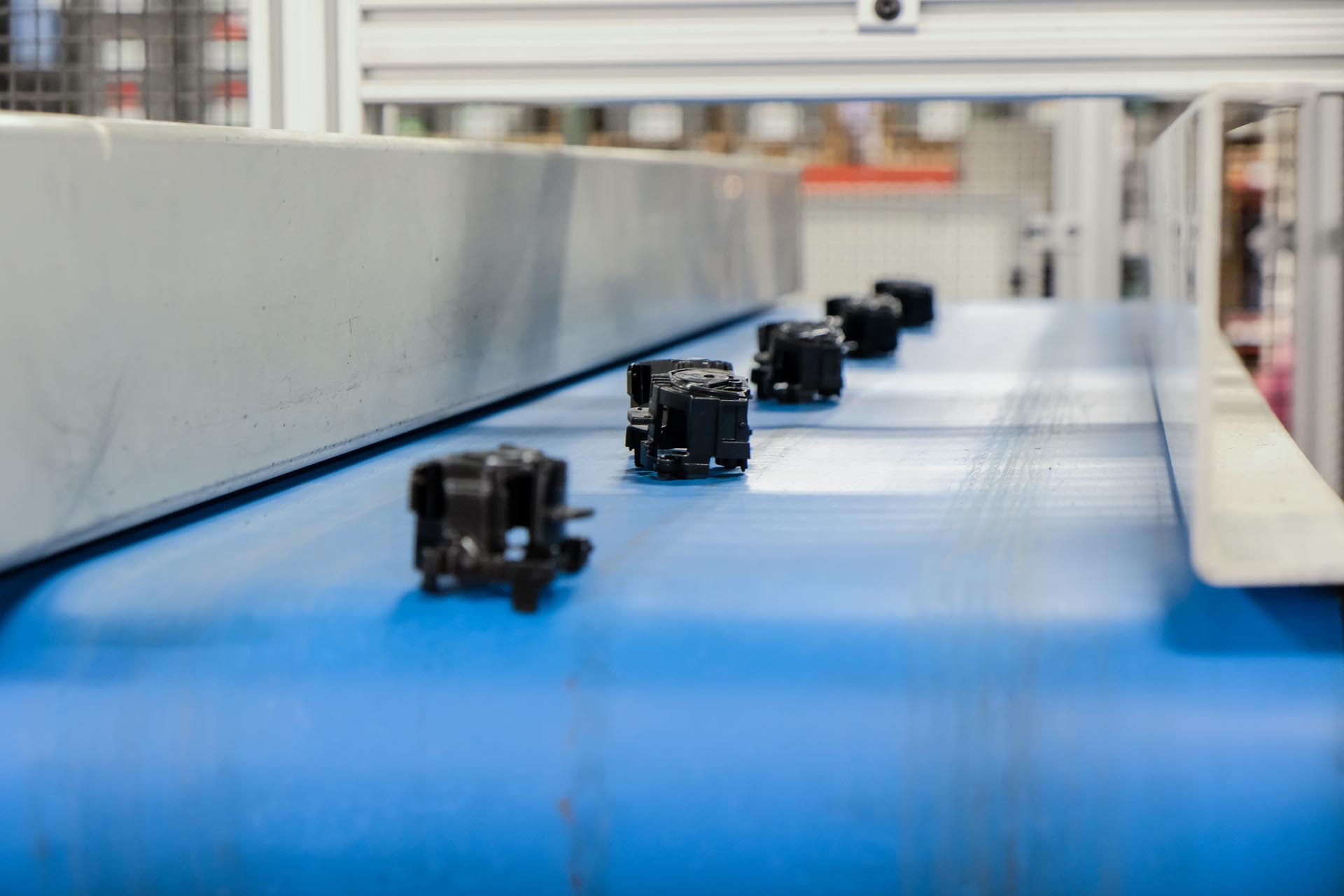

Automation utilized for insert loading, part handling, part sorting, and separating runners from parts. Letting our team members focus on what they are good at and reducing the repetitive tasks that robots are best at.